It is used to measure the deformation of metals, ceramics and composite materials at high temperatures generated by high-temperature furnaces and induction heating systems. Compared with other high temperature extensometers, it is easier to use and has better performance.

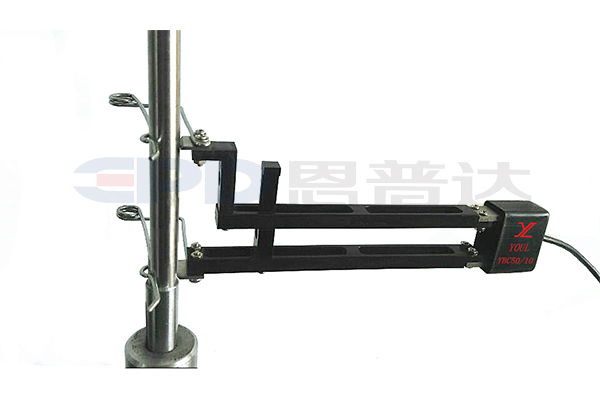

Fix the extensometer to the specimen with a very light flexible ceramic fiber thread. In this way, the extensometer clamps itself on the sample. No high temperature furnace mounting bracket is required. It is easy to install this extensometer with a high-temperature furnace for material testing with most side openings. For induction heating systems, the different placement of the ceramic wire allows the extensometer to pass through the induction loop easily.

Due to the effect of the radiant heat shield and convection cooling fins, the extensometer can be used in an environment where the sample temperature reaches 1200°C without cooling. The optional small fan can improve the stability of the extensometer at the highest temperature, so it is recommended to use it when high precision and small elongation tests are required. The fan has a magnetic base and can be placed in a convenient location near the extensometer. The induction heating system does not require fan cooling.

Use high-purity alumina (minimum 99.7%) ceramic rods. The appropriate length can be selected according to the requirements of the high temperature furnace. Tensile, compression and cyclic test (low cycle fatigue) strain measurement can be done with an extensometer.

For vacuum furnaces, water cooling extensometers can be provided. Radiant heat transfer cooling type extensometer is also available. This requires the extensometer module to be wrapped in a sink, leaving a gap in the ceramic rod in front of the sink.